This Vermiculite Coated Fiberglass Sleeve resists most acids and alkalis and is unaffected by most bleaches and solvents. It is highly flexible and conformable. This Sleeve is used to protect industrial wires, cables, hydraulic hoses, tube and pipe as well as affording personnel protection and energy savings.

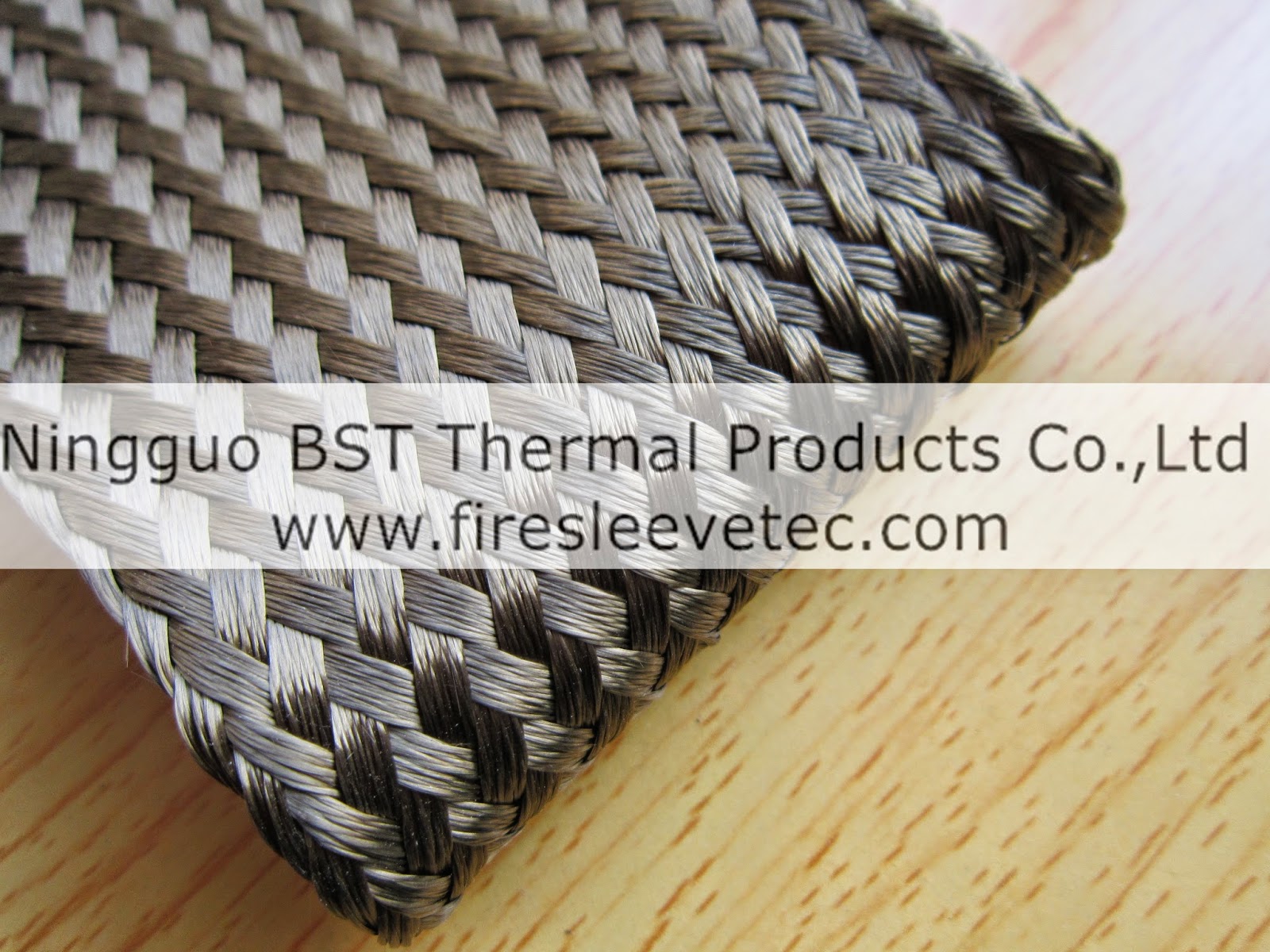

Vermiculite Coated Fiberglass Sleeve

Available in thin wall (1/16 in. / 1.6mm.) and thick wall (1/8 in. / 3.18mm.).

1500°F / 815°C continuous exposure with excursion to 2000°F / 1093°C.

Vermiculite adds Fire resistance, Anti-Fray and improved abrasion resistance and higher temperature capabilities which makes this sleeve a good insulator for hose, cable and copper or aluminum tubing

.jpg)

.jpg)